Elausa is an electronic contract manufacturer, covering all the processes of electronic design and manufacturing.

Our client provides a comprehensive service or may require involving Elausa in any phase of the process as required. From the electronic concept and design to the after-market service as well as the industrialization, manufacturing and logistic services.

We are specialists in the electronic subcontracting of any electronic manufacturing service (EMS).

Discover our electronic design and manufacturing services:

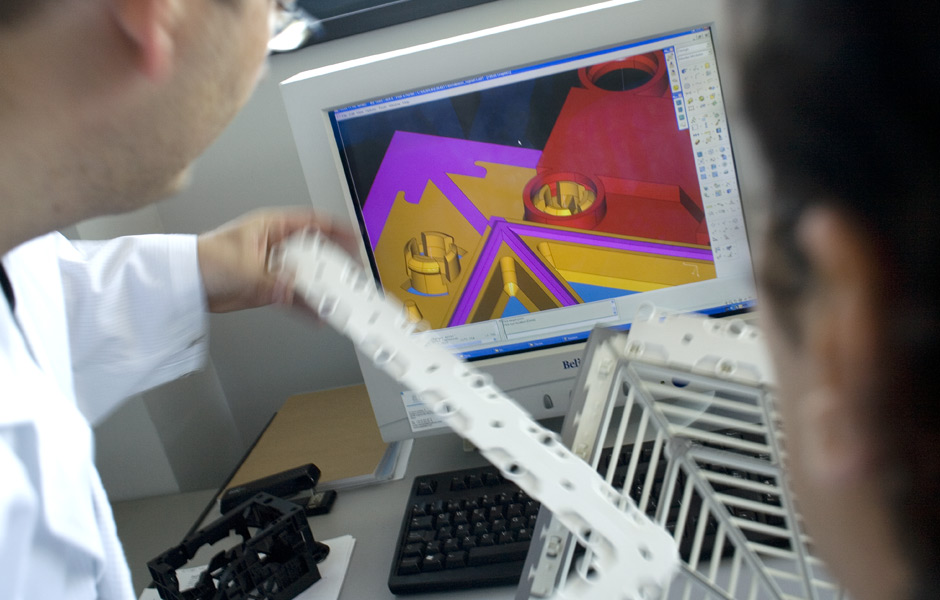

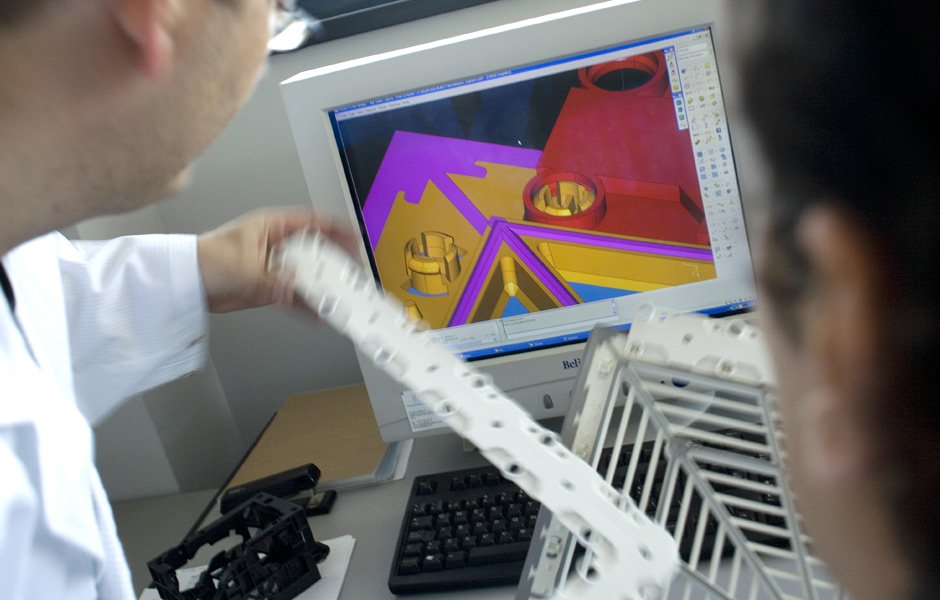

Electronic Design

The extensive experience, know-how and professionalism of Elausa’s R+D+I, engineers is made available to our customers as well as our technical resources and installations for developing the most demanding and innovative products as required.

We work closely with the customer’sdevelopment team and we take on their challenges as if they were our own: with maximum flexibility; and providing a full guarantee that yourintellectual property and critical information will be protected; speeding up the development and reducing the time-to-market .

We offer our partnership in all phases of design: from the idea to the concept; defining the specifications; developing the product; the prototypes and validation. Throughout this entire process we provide our experience as a manufacturer and guide the development process by anticipating to the challenges entailed by the subsequentindustrialization.

Our laboratory has the equipment required for conducting tests regarding de compatibilidad electromagnetic compatibility, electrical security , and optical performance, , as well asageing and environmental tests to guarantee the safety reliability and compliance with the standards applicable to the product.

Industrialization

We provide our know-how as a manufacturer to optimize the industrialization of the product. Our team of production engineerswill conduct a detailed study of each design and will plan our productive processes focussed on the obtaining of zero defects.

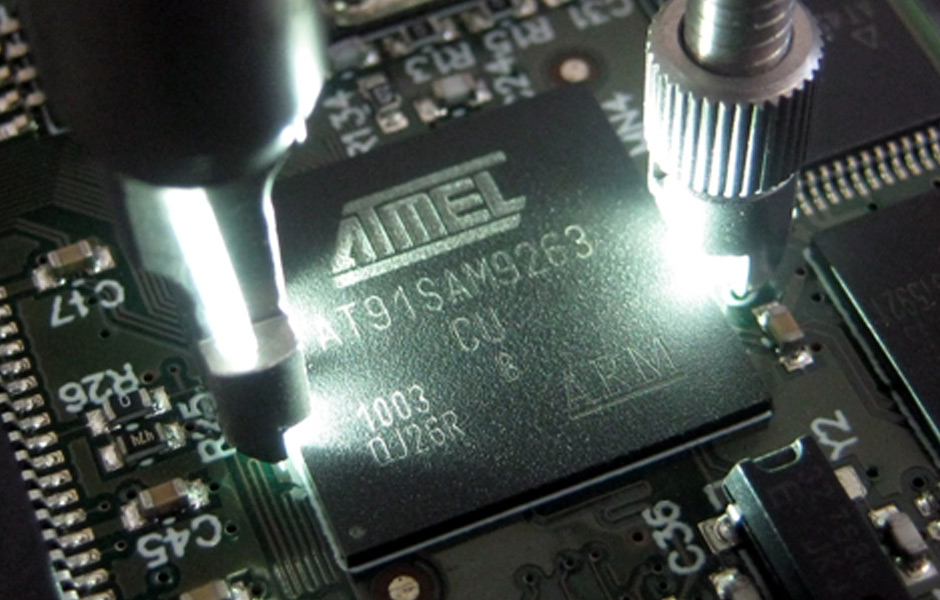

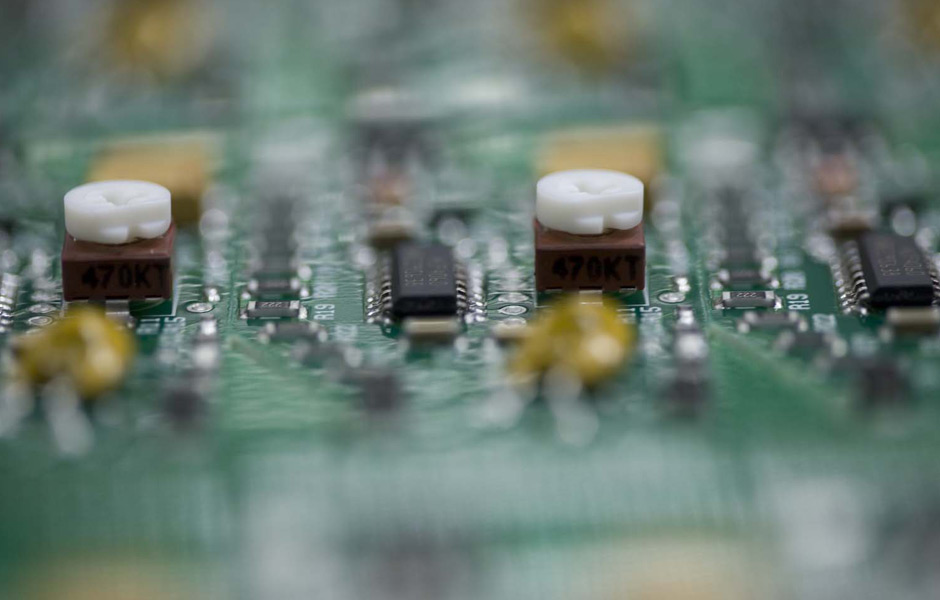

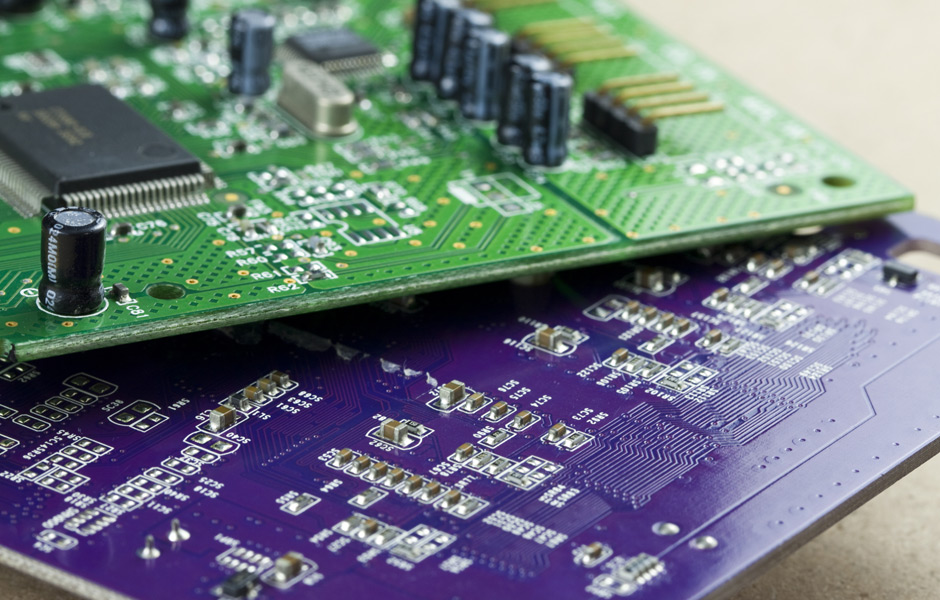

Manufacturing of electronic components

At Elausa we provide our customers with our know-how and experience acquired since 1988. A team of highly qualified persons , a modern manufacturing plant with state of the art machinery and a powerful information technology system enables us to guarantee the highest levels of quality and traceability.

Our manufacturing is flexible to provide service to specific needs of our clients in different sectors such as the automotive, industrial and electro-medicine sectors..

Verified manufacturing. 100% of the electronic equipment we manufacture are functionally checked.

Supplying / negotiating with suppliers of all types of components

We work with a panel of global suppliersand apply a continued assessment and qualification system to all suppliers.We focus on the quality and traceability of the components and on the power of negotiation to get competitive rates for our clients.

Reception, inspection of raw materials and stock

A Quality inspection of all raw materials that is completely recorded in our powerful information system, which fully guarantees its traceability.

We have:

- Automatic robotic warehouses integrated with our information system to ensure a secure stock and to prepare for the manufacturing with maximum efficiency.

- Dry atmosphere cabinets, in accordance with standard IPC /JEDEC J-STD-033 for humidity sensitive components.

- Components used for vacuum packing.

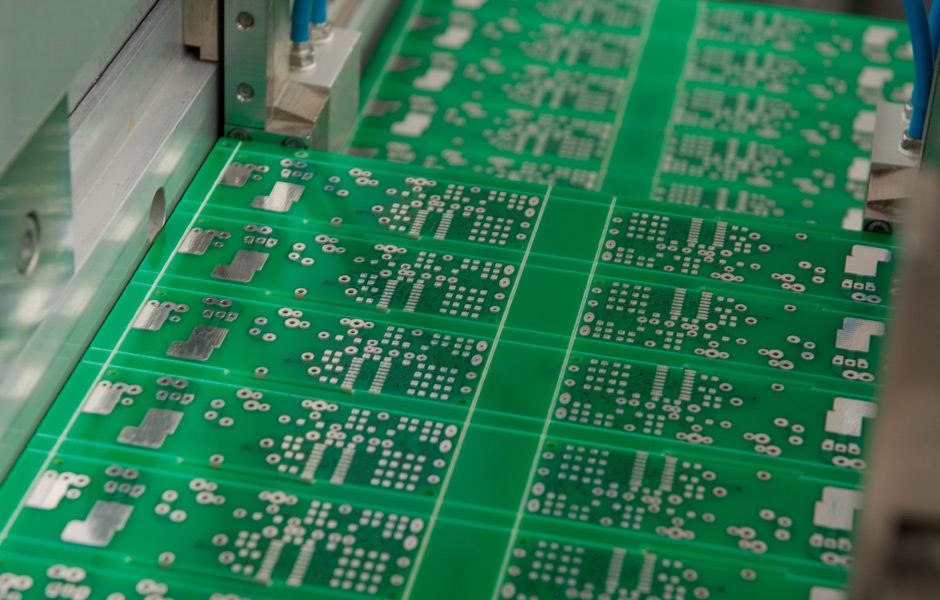

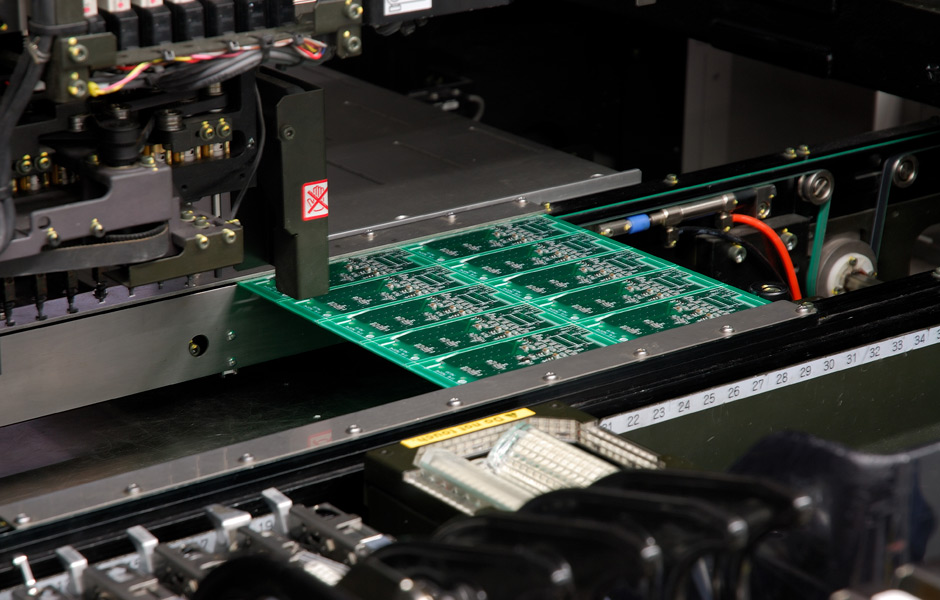

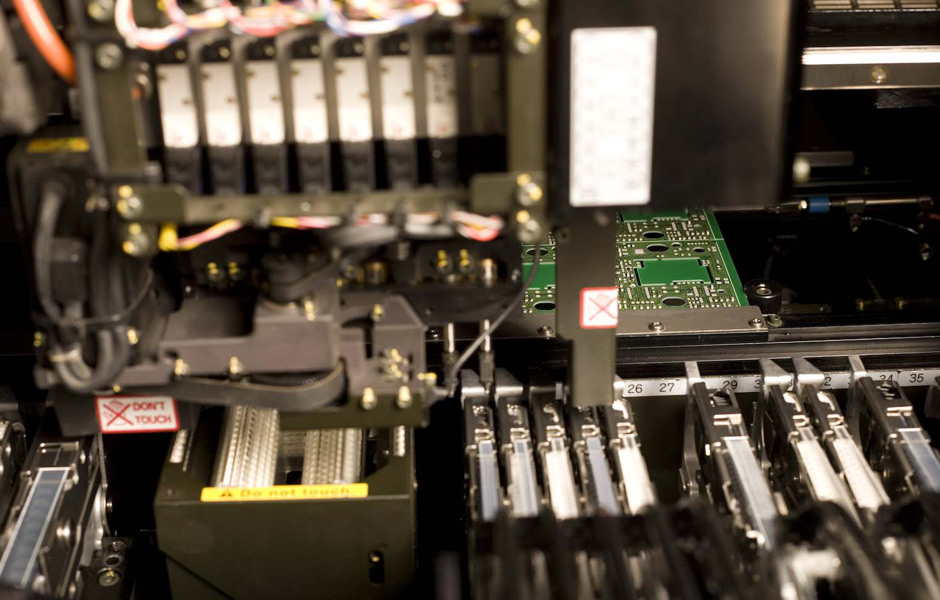

Assembling of electronic circuits

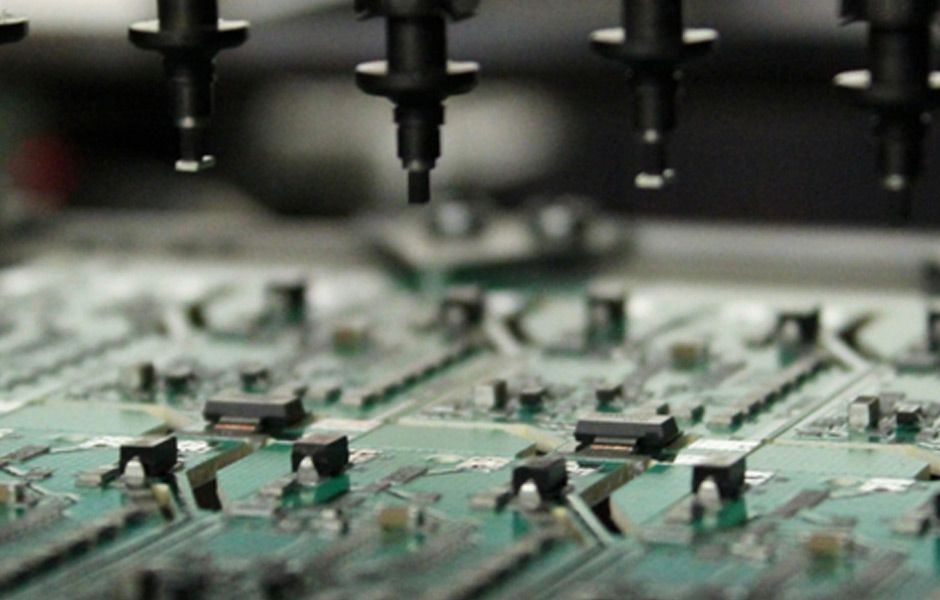

Assembling of SMD and true hole components

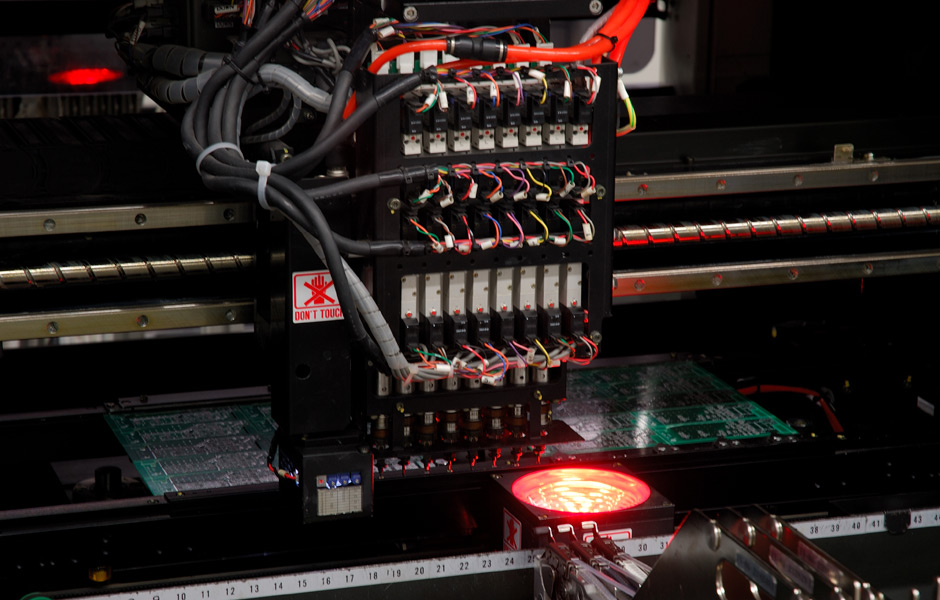

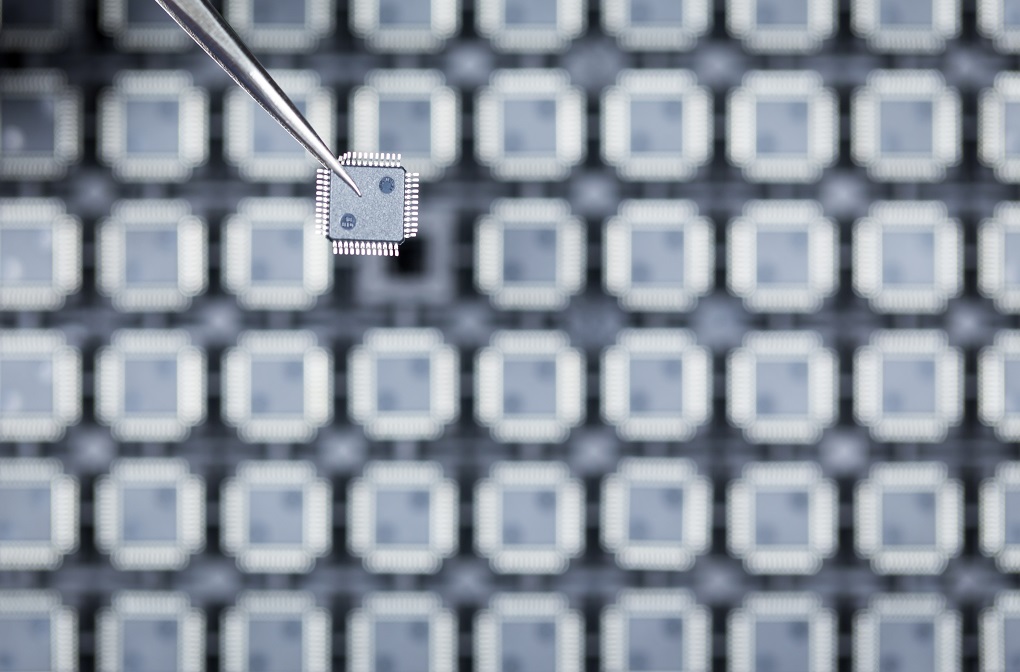

3 complete SMD assembling lines with an insertion capacity exceeding 120.000 components/hour.

Screen printing, with a repetitive positioning of 3 sigma: + /-0.005mm, with a 2D high resolution viewing camera.

Máquinas pick & place machines ready to install all types of encapsulates such as QFPs, QFNs, BGAs, uBGAs, LGAs, CSPs, POPs (Package on Package), fine pitch components with a pitch lower than 0.5 mm, uBGA with a pitch lower than 0.4mm and with a ball diameter lower than 0.1 mm, as well as components with a wide range from 01.005 to 45x 100mm.

Reflow ovens with 7 areas, with controlled temperature profiles in accordance with standard IPC, JEDEC J-STD-020.

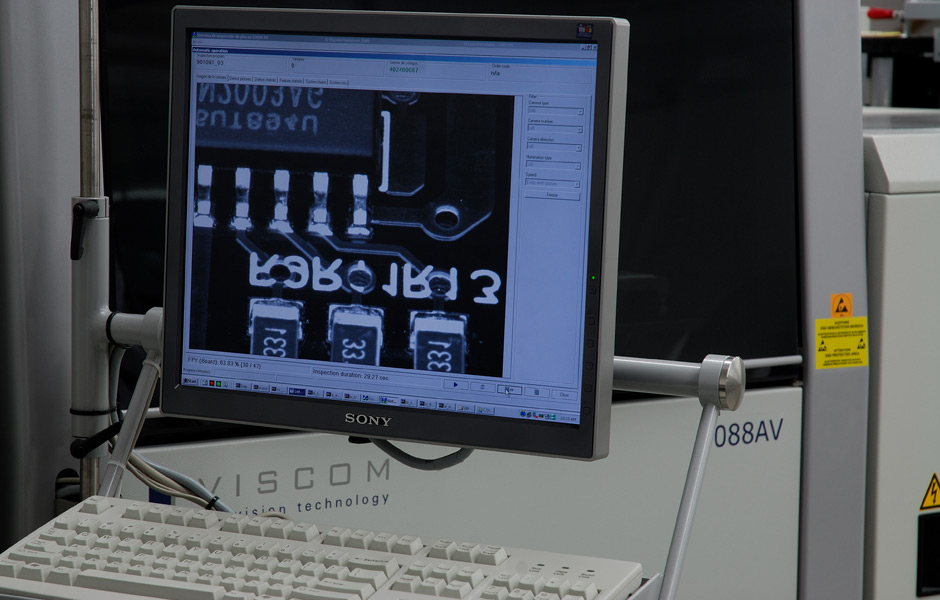

AOI inspection, checking position, presence / absence, polarity, quality of welds and values as applicable.

Assembling of true hole (THT) components

We have Royonic machines to help install THT or conventional components. We install all types of special elements and cables.

Soldering

Wave soldering with lead free solder (RoHS) Selective soldering.

Tropicalization

We have automatic lines for applying silicones, polyurethanes and varnishes to tropicalize the circuits.

Automatic machine with 5 axes and automatic nozzle replacement. Over-injection with hot melt.

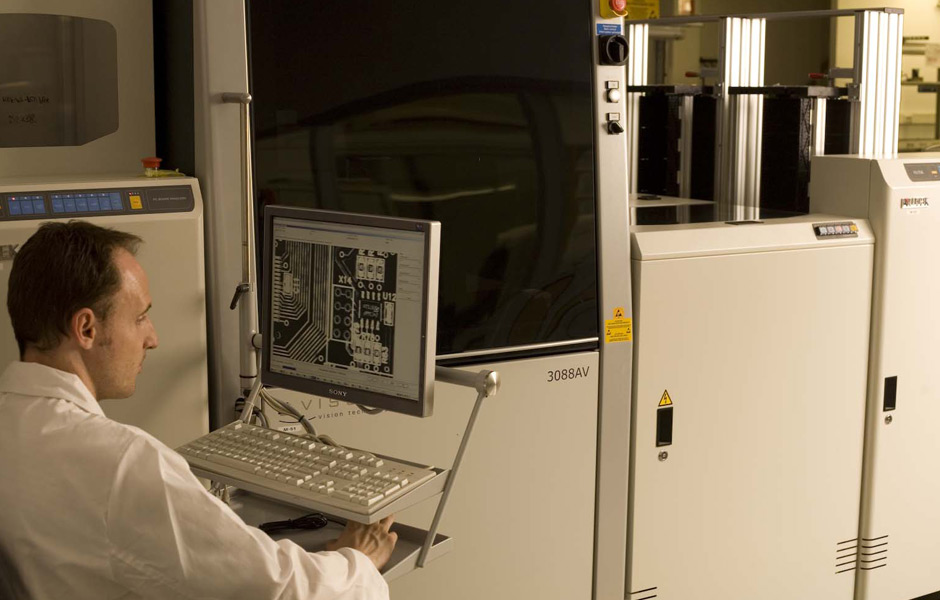

Checks

Elausa supplies quality products; the company’s policy is to ensure that a functional check is carried out on 100% of the electronic circuits and products we manufacture prior to delivering them to the client.

The process of functionally checking the manufactured electronic components is agreed with the client.

The test checkers and tools are manufactured at Elausa or are supplied by the client depending on the agreement.

Integration of services

Jointly with Array(the group’s plastic division), we develop and manufacture plastic injected parts from plástico inyectado: desde optical lenses to structural or aesthetic parts that are integrated with the electronic circuits.

We also assemble other electronic and mechanical systems to our electronic and plastic components in order to supply a fully finished product to the client, even with the packaging personalized, with instructions and perfectly prepared to be sent to the end customer.

Logistics

Elausa handles all the logistics and the supply chain associated with the electronic manufacturing in a manner that is flexible and adapted to your needs and schedule.

We take responsibility of all the logistic phases from managing purchases, stocks and storage, traceability, packaging and shipping.

Managing the purchasing of components and materials

The distribution of electronic components market is complex and greatly effects customer service parameters such as lead time, quality, flexibility, competitiveness and price. Our Purchasing and Quality departments select, negotiate and evaluate the panel of suppliers and coordinate with the Production department to optimize these service parameters.

We have a powerful comprehensive ERP management software for managing the entire process.

Storage and stocks

Maintaining a suitable stock level to ensure the service to the supply chain is as important as having proper installations to ensure the quality of the materials and an efficient management of their supply chain. At Elausa we have robotic warehouses integrated with the ERP, dry atmosphere cabinets in accordance with standard IPC / JEDEC J-STD-033 and vacuum packing elements.

Traceability

It is essential to maintain a positive traceability of the raw materials, products in progress, finished products as well as the productive processes involved in manufacturing each product. Elausa has a traceability system built-in to the comprehensive ERP management software.

Packaging and Shipping

The packaging is another essential aspect to ensure the quality of the service and product. Elausa adapts to the packaging requirements for each delivery regarding both the materials as well as the procedures and we will design specific packages if required. We also manage shipping operations to ensure the level of service to the client.

The identification of the brand’s image and differentiating each product and company is very important in order to be successful in the market. Elausa is able to deliver a fully finished product to the customer, with the personalized packaging with the brand’s image, including manuals and documentation as well as everything required so that our customer receives the product just as it will be received by the end customer.

Flexibility

Elausa is flexible and adapts to the customer. Our offer to the customer includes adapting the logistic and supply processes as required in each case in a manner that is personalized for each customer.

After Market

Technical service

We provide technical assistance to our customers that covers analysing, repairing and updating the manufactured equipment. We collaborate with the customer to solve the problem, improve the robustness of the product and apply the required modifications.

Spare parts

We have a stock of spare parts that guarantees we can repair your equipment if needed.

We also schedule the manufacturing of spare parts as required to meet the legal requirements, which stipulate the amount of time we are required to supply spare parts.

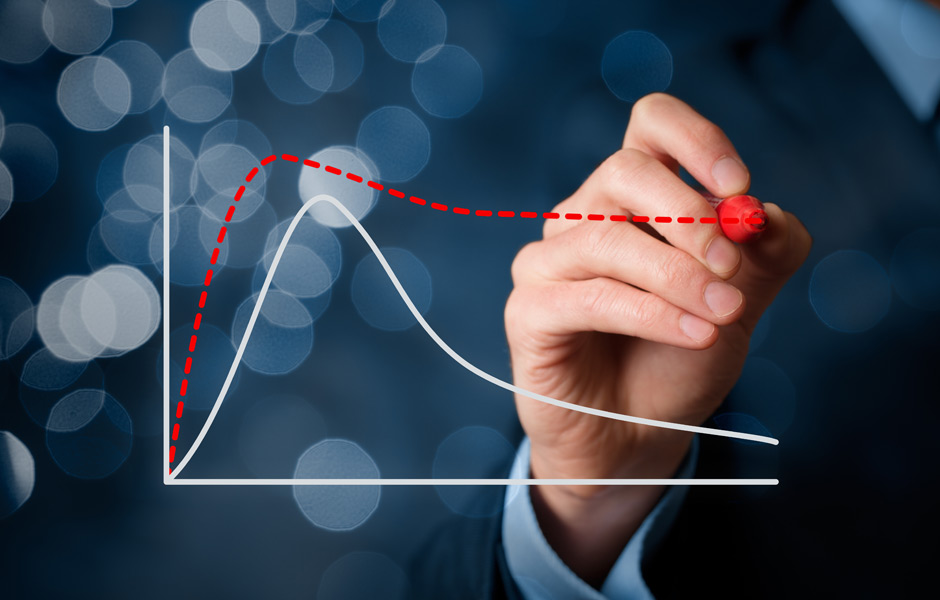

Redesign to extend the life cycle of the product

Maintaining our position in the market entails evolving the product based on the needs of the market by incorporating the new technical developments that become available. The redesigning of the product is also a tool to optimize the manufacturing costs.

We become involved in this process to extend the life cycle of the product.